REHABILITATION PIPE

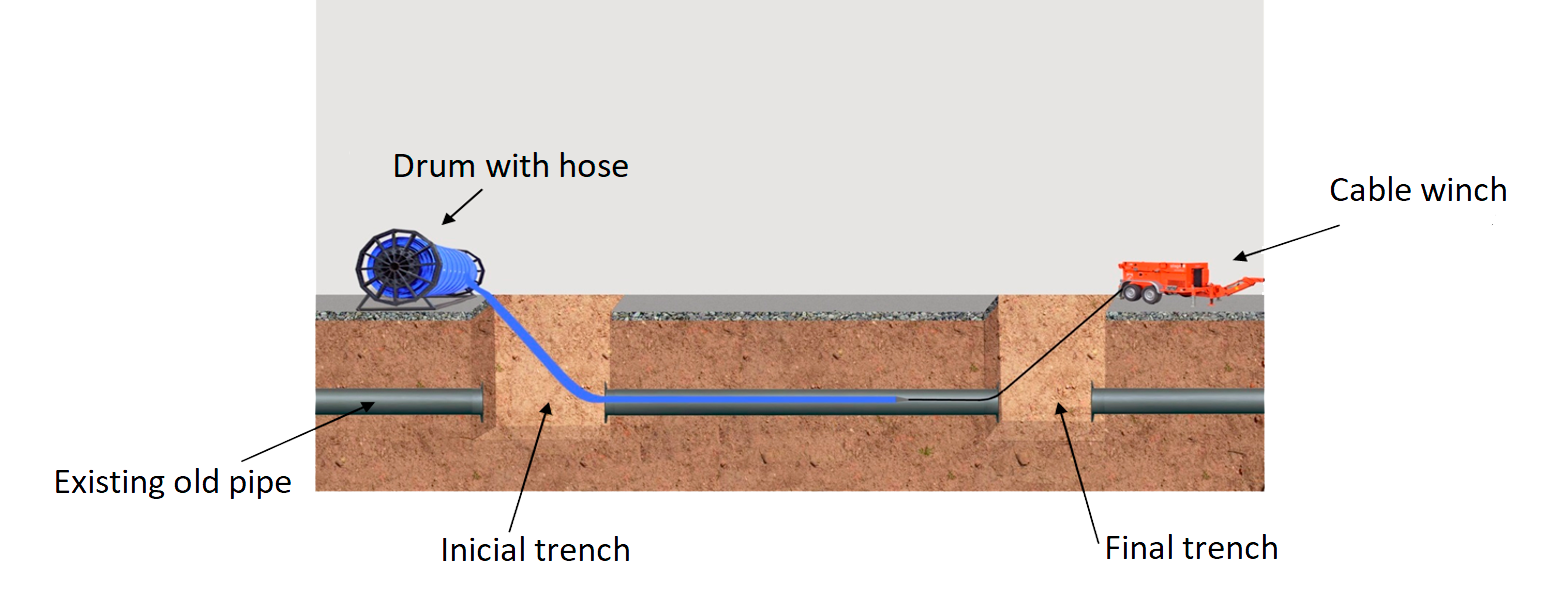

PRIMUS LINE® is a trenchless technology for the rehabilitation of pressure pipes for different media such as water, gas and oil. The system is based on an interlaced high pressure flexible composite tube and a specially developed connection technique.

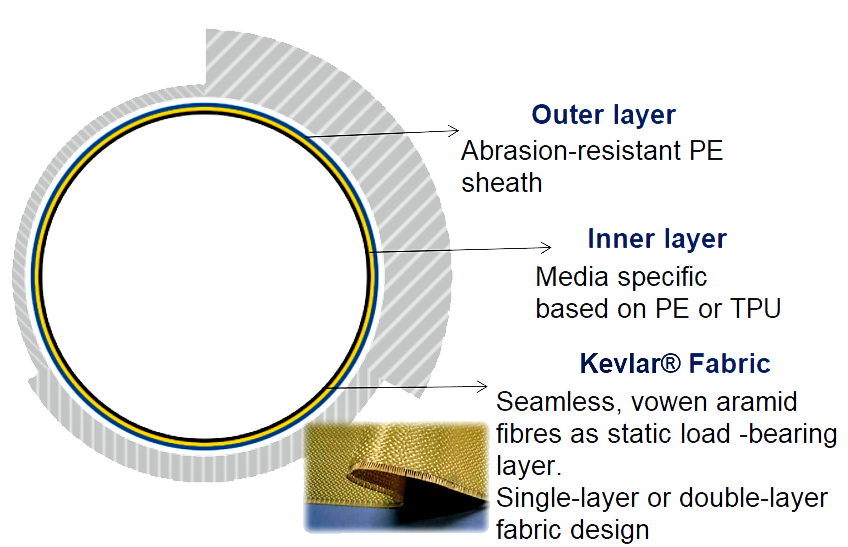

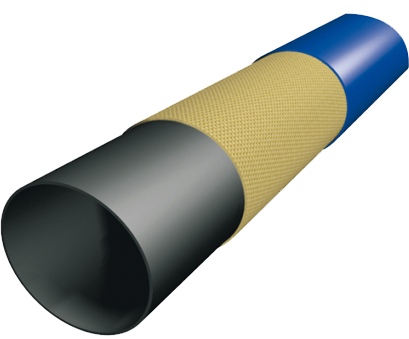

PRIMUS LINE® is a reinforced high density polyethylene pipe system that offers an extremely resistant material due to multiple layers, with a reduced thickness.

ADVANTAGES:

Simple application:

- Reduced use of machinery

- Little construction time due to large insertion lengths.

- Small ditches of construction, reduction of excavations in general.

- Possibility of curved constructions.

- Insertion also through elbows up to 45 °

- Quick resumption of service

High load capacity and quality:

High load capacity and quality:

- Minimum 50 years of lifetime

- High resistance to wear and tear of the external coating.

- No corrosion

High performance capacity:

- Minimum loss of cross section due to lower wall thicknesses of 6.0 or 8.0 mm

- Improved pipe flow properties

- Pressure increase in existing pipes

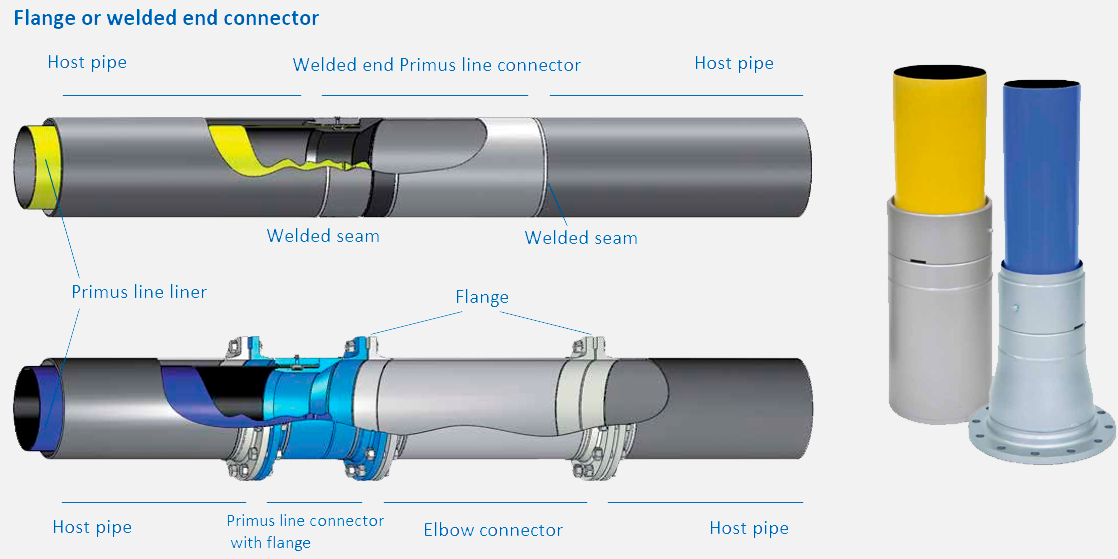

Depending on the requirements, the Primus Line® connector can be provided with a flange or a welded end. For this reason, it is also possible to connect elbows, T pieces or other pieces and taps (of different materials).

Unique trenchless system for rehabilitation

A relining system that is currently more suitable than any other existing system in the world to rehabilitate damaged pressure pipes in a diameter between 300 – 500 mm (6 “to 20”), several banks and a single length of 300-3,000 m (1,000 to 6,000 feet) in a sensitive and difficult environment, quickly and reliably.

It consists of inserting a new pipe, inside an old pipe to be replaced, being the hydraulic and static conditions of the same quality as installing a new pipe.